Top 4 Causes of Hydraulic Cylinder Failure

Listed below are the top 4 causes of cylinder failure. A proper equipment inspection, regular training, and a preventative maintenance plan can all decrease the chances of these common cylinder failures.

Listed below are the top 4 causes of cylinder failure. A proper equipment inspection, regular training, and a preventative maintenance plan can all decrease the chances of these common cylinder failures.

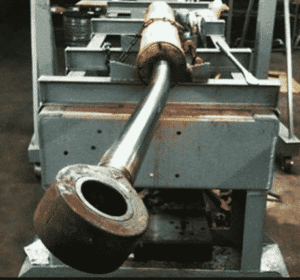

1. Sideloading

Sideloading is the most common cause of wear and cylinder failure. A common result of sideloading is cylinder misalignment, which creates an unusual force on the piston rod. A side load of enough magnitude can result in tube scoring, piston rod, and rod bearing wear, and even seal failure.

2. Contaminated Fluid

Contaminated fluid can cause premature rod seal failure. Abrasive particles in the fluid can damage the seal and the piston rod surface, airborne contamination can be drawn into a cylinder by a faulty wiper seal. Contamination occurs in numerous ways, the most common is drawn in from oil or from the pump.

3. Ensure proper Fluid Conditioning

Check for and remove any dirt or foreign materials in the hydraulic fluid. Be careful not to introduce aerated fluid which can cause sound level issues. Verify the filtration system is operating properly. Finally, inspect filter elements for clogs and replace them as necessary.

4. Rough or scored rod

It is crucial to ensure the cylinder rod is in good condition. Rough places on the rod damage the seals and reduce their normal life resulting in the necessity for frequent replacement. Be sure to inspect the rod finish as well. Worn seals are caused by too smooth of a finish, while leakage past the seal is caused by too rough of a finish.

Have questions about replacing your hydraulic cylinders? Contact us today to discuss all your hydraulic cylinder needs or give us a call at 1-888-771-1894.