Why a Custom Hydraulic Cylinder is Right for You

With advanced technological software and enhanced engineering capabilities, custom hydraulic cylinders may be the best option for your mobile and industrial machinery needs. While standard cylinders can accommodate most needs, there often remain issues not addressed with standard cylinders. Design and engineering factor into how well your hydraulics can adapt and perform reliably.

Custom hydraulic cylinders offer you the ability to work with experienced hydraulics engineers on a cylinder built to your specification needs. Learn how a custom hydraulic cylinder can be the right solution for your hydraulic system requirements.

What Makes Custom Hydraulic Cylinders Different?

Performance matters when it comes to hydraulics. Whether your workday requires using light-duty or heavy-duty hydraulic cylinders, you still need a hydraulic cylinder that can withstand your work demands. While standard hydraulics cylinders can meet your workday needs, custom hydraulics give you complete freedom to manufacture a cylinder based on specific cylinder requirements.

With custom hydraulic cylinders, you can:

- Design a cylinder with varying load capacities

- Material choices including stainless, carbon, or alloy steel

- Custom stroke lengths

- Multiple or single rod designs

- Large bore diameters

- Custom sealing options

- Mounting options

- Temperature range customization

- Integrated valve options

- Tech integrations like computer-aided or position sensing options

- Custom paint and finishing

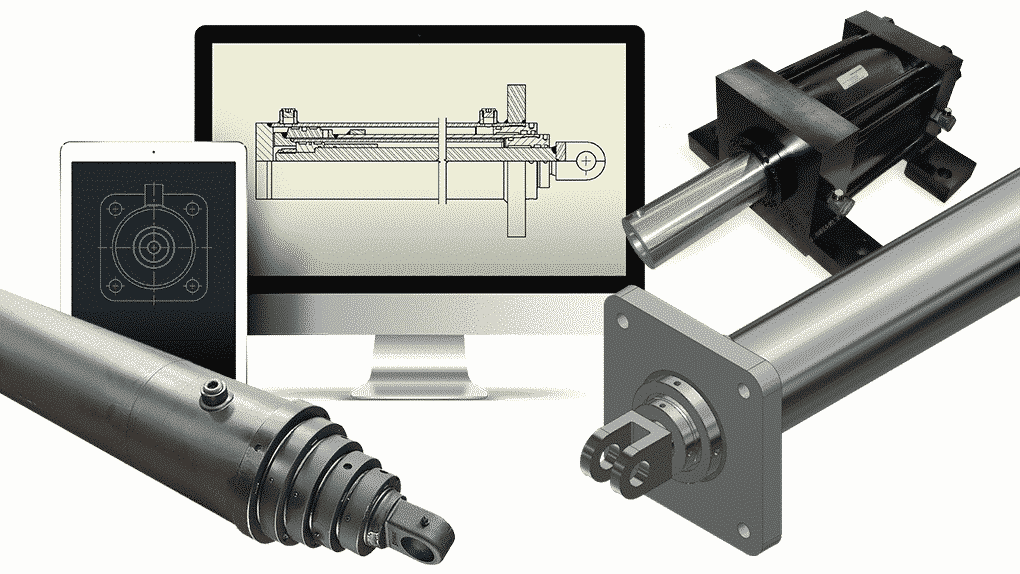

Design and Engineering for Custom Hydraulics

One of the biggest factors for custom hydraulic cylinders relates to the design and engineering capabilities available to you. When you work with a trusted hydraulic cylinder manufacturer, you have access to their design and engineering team. Industry-leading hydraulics suppliers like HCI have a team of engineers and hydraulics experts that utilize state-of-the-art facilities as well as advanced CAD modeling software.

Custom hydraulics allow you to pinpoint potential design weaknesses before your cylinder is built. 3D modeling and analysis provide you with added insight where you can make the necessary adjustments for complete hydraulic cylinder design optimization.

How You Can Benefit from Custom Engineered Hydraulics

With unlimited design options and access to an experienced engineering team, the benefits of custom hydraulics are immeasurable. Perhaps your current cylinder is made from carbon steel and a stainless steel cylinder would be better suited for your needs. Extreme temperatures and operating conditions can play a crucial role in how reliable your hydraulic cylinder performs. With customization, you can build a hydraulic cylinder that you can trust to work regardless of the work environment.

Custom seals, mountings, port sizes, and valves allow you to design and manufacture a cylinder with long-term dependability that can save you time and money. Custom hydraulics built for your work demands can decrease the chances of continual maintenance and repair issues. Standard hydraulic cylinders that are not built to withstand harsh work environments often lack the rugged dependability afforded by custom-designed cylinders.

Work with a Trusted Hydraulic Cylinder Manufacturer

Ready to design your custom hydraulic cylinder? Request a quote or use our custom rod cylinder app and build your custom hydraulic cylinder today.

Want to learn more about custom hydraulics? Check out our blog posts that detail different aspects of custom hydraulics including maintenance tips and hydraulics how-tos.